AmSys leak detector performance

The AmSys (Adaptive Measurement Systems) Leak Detection Unit provides a number of improvements over existing measurement principles. The solution gives a significant improvement in sensitivity that is maintained over time by the adaptive functionality. In combination with the nearly maintenance free conductivity measurement principle this gives an unmatched performance.

Standard conductivity sensors are normally mounted directly in the process piping, allowing fast detection in case of a leak. The sensors are available for nearly all pressures and temperatures.

The AmSys Leak Detection Unit may be used in all systems where leakage can be detected as change in conductivity through the heat exchanger. Typical applications are leakage of ammonia or seawater into water or water/coolant mixtures.

According to EN 378-3, heating/cooling systems with more than 500 kg ammonia (R717), detection must be installed the cooling / heating secondary circuits.

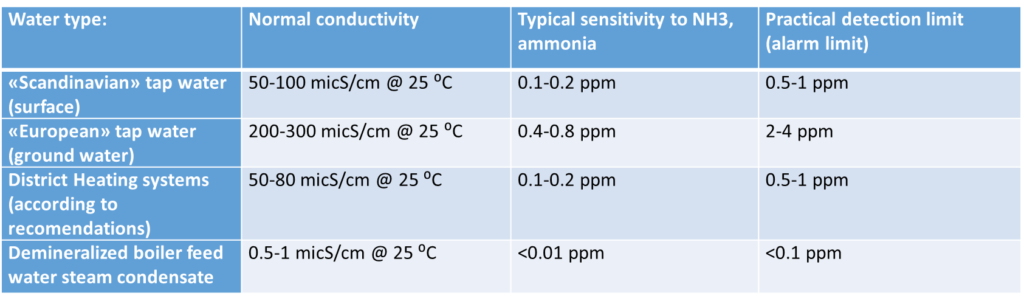

Typical AmSys sensitivity is shown in the table below:

Preliminary tests on ammonia in seawater indicates 10- 30 ppm as practical detection limit, depending on seawater salinity. This is well below most recommendations!

Amsys Leak detector advantages

The AmSys (Adaptive Measurement Systems) Leak Detection Unit provide a number of improvements over existing detection principles. Most important are:

- The AmSys solution nearly eliminates the need for maintenance and re-calibration. The adaptive functionality will compensate for slow changes due to sensor fouling and fluid conductivity.

-

High accuracy temperature compensation (linear and nonlinear) gives optimal signal stability over a large temperature range.

-

Sensors mounted in-line and sensor time constant compensation ensure short alarm delay in case of leak

-

Sensors are virtually maintenance free and are available for nearly all pressures, temperatures and conductivities.

-

With its improved sensitivity, the ability to detect leaks in their infancy is significantly improved, often allowing detection and repair before there is any impact to the environment. This can be very advantageous as most problems start with a “small” leakage.

The AmSys solution, main features:

⦁ The AmSys solution is adaptive.

Measurements from the applied instruments are analyzed and used to define a mathematical model of each of the sensors and the complete system. Since the models are updated individually and continuously during operation, optimum accuracy is ensured at all times. This also ensures that deviation and drift due to changes in water quality, sensor wear, sensor position, soiling etc. do not compromise unit sensitivity or generate false alarms.

Main features of the AmSys adaptive model are:

⦁ Optimal temperature compensation, linear and nonlinear.

NOTE: Only a small 0.1% error in the temperature compensation factor will become 2% if the temperature variation is 20 ⁰C.

⦁ Sensor time-constant and deadtime compensation.

Difference in dead-time and time-constant cause large error in the measurements when temperature rise of fall.

⦁ Conductivity variation compensation.

Needed since conductivity sensors and transmitters are never absolutely 100% equal. Even if they were, they will soon become different when mounted in the process due to mounting position, fouling, wear etc.

⦁ Transport time compensation.

Latency/transit time between the measuring points will result in measurement errors and false alarms if variations in conductivity is present.

⦁ Advanced alarm filtering and limit optimization.

This allows for operation with narrow alarm limits without getting false alarms, but without compromising fast alarms in case of a large sudden leak.